Background:

Quartz sand purification is removal of a small number of impurities and the high difficulty separation technique to obtain refined quartz sand or high purity quartz sand. The purification technologies of quartz sand at home and abroad are washing, classifying and desliming, scrubbing, magnetic separation, flotation, acid leaching, microbial leaching, etc.

Solution:

- Two-stage closed-circuit crushing-one-stage self-grinding and lead roughing concentrates regrinding-differential flotation-two-stage dewatering.

- After the raw ore was ground, lead concentrates were produced through one-stage roughing, three-stage scavenging and three-stage concentration, with a recovery of 92%.

- The dehydration operation was carried out by disc vacuum filter, and the dehydration rate was more than 95%.

Feedback:

Silicon dioxide 99.5%, ferric oxide 0.14%, aluminum oxide 0.54%,used for glass making industry

.jpg)

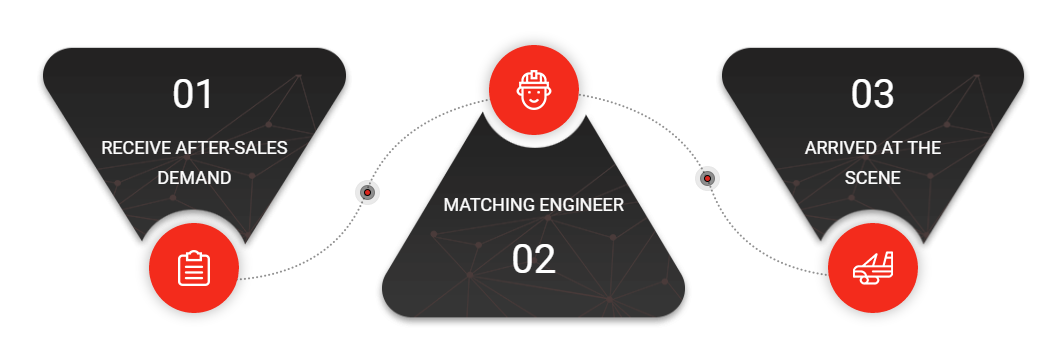

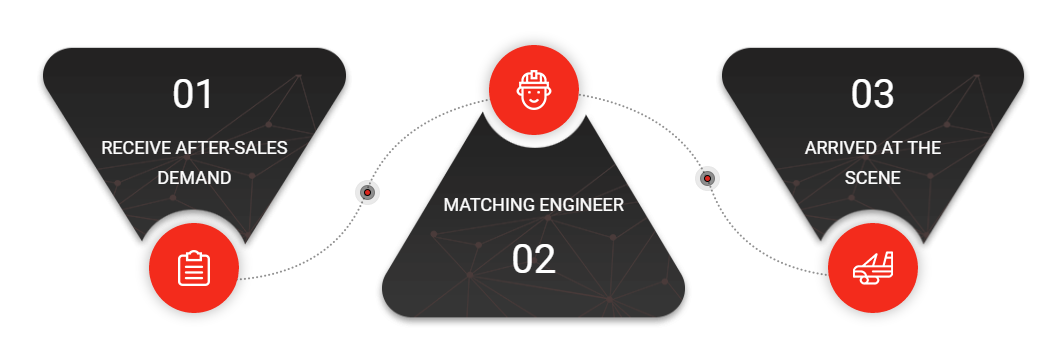

Service support:

- 48-hour idling test machine before leaving the factory.

- You can take the materials to the factory test machine.

- We will customize the solution according to your needs.

.jpg)