Background:

The metallic minerals were magnetite, hematite, limonite; the non-metallic mineral was quartz. Only Fe in the raw ores has recycling value, and the raw ores belong to original acid magnetite with low phosphorus and low sulphur.

Process

- Crushing and screening stage: The process of three-stage crushing and screening with single closed-circuit stage was adopted.

- Grinding and magnetic separation stage: The process of stage-grinding and stage-separation was adopted.

- Concentrates dewatering stage: Magnetic concentrates were dewatered preliminarily by concentrated magnetic separator.

- Tailings dewatering stage: The tailings were firstly processed by thickeners for the first-stage dewatering; after that, the underflow was transported by the slurry pump to hydrocyclone for classification.

Feedback:

The project adopted advanced, sound and energy-saving equipment and simple auxiliary facilities to cut construction costs and increase output. There was no environmental pollution, meaning that no waste water was discharged.

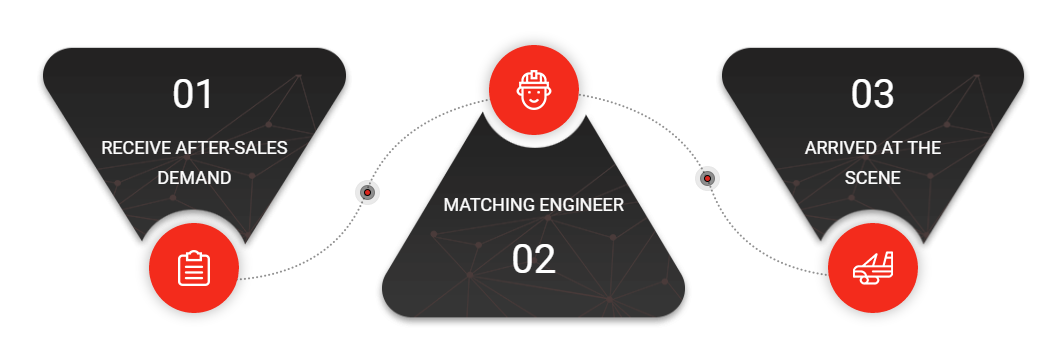

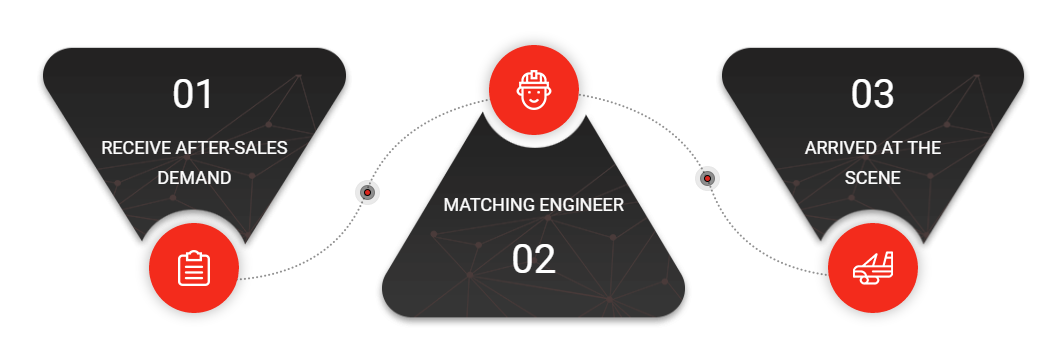

Service support:

- 48-hour idling test machine before leaving the factory.

- You can take the materials to the factory test machine.

- We will customize the solution according to your needs.