The Uzbekistan customer's 300TPD cement production line is started in 2019. It is mainly used to produce ash cement, and the finished product is used in the field of building materials. After detailed visiting to the Hongji’s production site, the customer selected Hongji's complete equipment including 2.4x10m and 2.4x11m mills, 3.0x60m rotary kiln, burner, dust collector, hoist, storage bin, feeder, A complete set of equipment such as electric control cabinets.

Process Flow:

Limestone, clay and iron powder are crushed, mixed into a raw ball mill for grinding, and then lifted to a four-stage preheater by a hoist, and then heated into a rotary kiln for calcination, Calcined clinker and gypsum, slag is mixed again, etc. The mixture is grinded again to obtain cement.

Program details:

Processing materials: limestone, clay, iron powder

Production: 300 tons / day

Configuration equipment: 2.4x10m and 2.4x11m mill, 3.0x60m rotary kiln, burner, dust collector, hoist, storage bin, feeder, electric control cabinet, etc.

Project address: Uzbekistan

Project Feedback:

Hongji Mining Machinery has designed a reasonable plant based on the customer's site topography. At present, the entire process equipment has been operated and achieved considerable revenue.

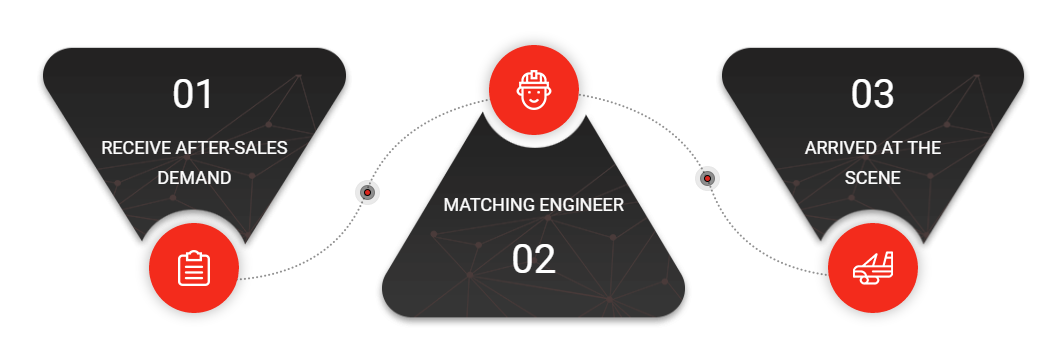

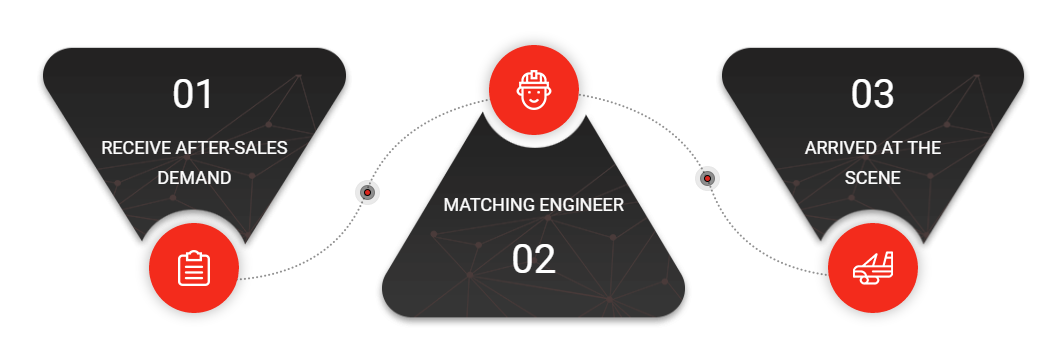

Service support:

- 48-hour idling test machine before leaving the factory.

- You can take the materials to the factory test machine.

- We will customize the solution according to your needs.